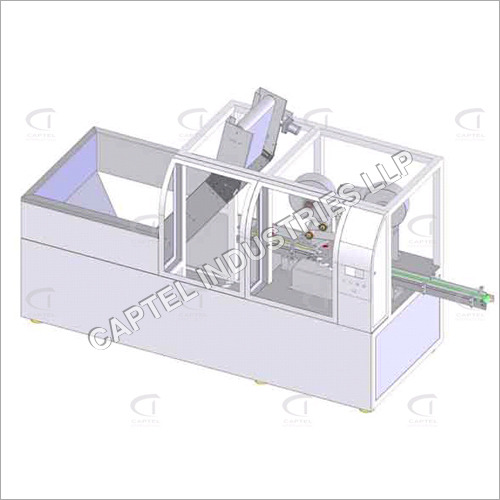

Liner Cutting & Wadding Machine

Product Details:

- Voltage 220-440 Volt (v)

- Machine Type Liner Cutting & Wadding Machine

- Frequency 50 Hertz (HZ)

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Coated

- Color Silver

- Click to View more

X

Liner Cutting & Wadding Machine Price And Quantity

- 1 Piece

Liner Cutting & Wadding Machine Product Specifications

- 1 Year

- Liner Cutting & Wadding Machine

- Coated

- 50 Hertz (HZ)

- 220-440 Volt (v)

- Electricity

- Silver

- Industrial

- Semi Automatic

Liner Cutting & Wadding Machine Trade Information

- 100 Piece Per Month

- 7 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

Product Description

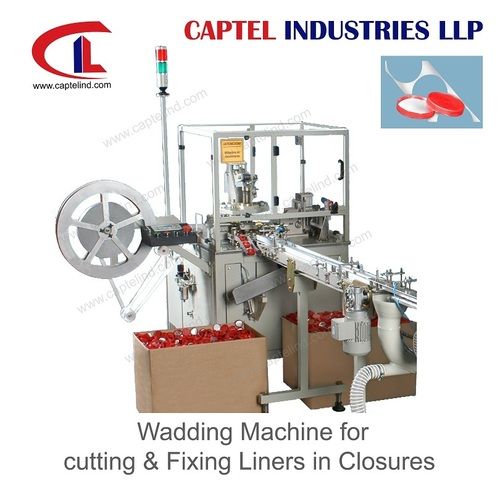

Liner Cutting Wadding Machine

The machine is capable of Cutting Liners from Rolls and inserting and fixing these cut wads into the caps in a single operation The caps will be loaded into a Vibratory hopper or Elevator Hopper manually The feeder supplies the caps adequately as required to the machine in the oriented fashion The conveyor transfers the cap to a dial where the caps are indexed at predefined locations The Liners in Rolls are fed onto the In feed rollers and cut just in time before the wad punching station The Liner drops into the Cap and when the cap and the wad moves to the next station a pusher pushes the wad into the cap and is firmly fixed The assembled cap will be counted and will exit from the coveyor The machine will be capable of handling various types and sizes of caps and wads with the help of change parts

Available with or without Hot Gluing System

Speeds Available 60 and 120 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese